From Fruit to Fabrics (Part 1)

“So, which fruit are you wearing today?” Might sound like a ridiculous question to ask, but it could very well be the reality in the next decade or so.

In this article we turn the spotlight towards biofabrics, fabrics that are made from renewable sources like plants, bacteria, algae, fungi roots etc. The problem of food and agricultural waste isn’t new, about 1.3 billion tonnes of food produced is disposed of every year. Biofabrics are one of the answers to reduce the amount of waste, leading to a circular economy.

Meet the top brands on the cutting edge of sustainable innovation, solving fashion’s waste issues one thread at a time.

Piñatex

It all begins when Dr. Carmen Hijosa, a leather expert, resolved to find a more sustainable alternative to leather, after being horrified by the environmental impact of mass leather production and tanning. Ananas Anam, the company founded by Dr Carmen, researched for years to invent Piñatex. The textile is derived from an unlikely source: pineapple leaves. Waste from pineapple harvests, leaves included, are traditionally burned or discarded.

Pineapple leaves require no additional land, water, fertilizers, or pesticides to produce, which makes it much more low impact than PVC and animal-based leather. Since they’re byproducts of existing pineapple farming, their harvest creates an extra source of income for rural agricultural communities in the Philippines, where Ananas Anam sources their raw materials. The production process is circular as residual biomass is used as a natural fertilizer. No chemicals on the Cradle to Cradle list of prohibited substances are involved in production either.

Like actual leather, Piñatex is water-resistant, pliable, and durable, without the environmental costs. The vegan leather alternative comes in various thickness and finishings, and colors dyed using GOTS-certified pigments. The textile has been welcomed with open arms from fashion to furniture companies, including Tamasine Osher Design, Nae Vegan Shoes, Hozen, HFS Collective, and Hugo Boss.

However, Piñatex is not 100% biodegradable due to its use of synthetic coating, such as a PU coating for its Performance collection and resin for its Original, Mineral, and Pluma lines. The good news is, Ananas Anam is developing a bio-based finishing so that the leather alternative is 100% biodegradable.

Mylo

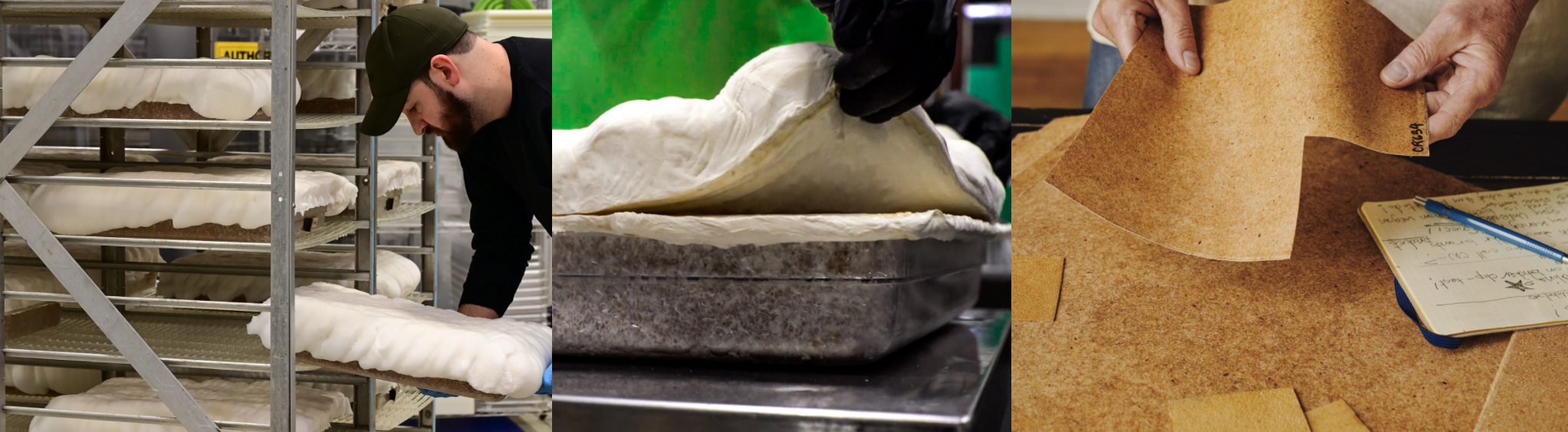

Mushrooms are everywhere you look, even thriving in unthinkable places. Bolt Threads, a California-based company decided to harvestness the resilient nature of mushrooms, and turn it into Mylo, a bio-leather that looks and feels like animal leather.

The creation of Mylo begins with Mycelium, a complex network of underground fibers that mushrooms and other fungi use to grow, much like tree roots. The network of mycelium cells are fed with sawdust and organic biomass, and placed on trays to incubate for two weeks. During the two-week period, the mycelium grows into a foamy layer in a humidity and temperature-controlled environment. At this stage, the mycelium network can be tweaked at the genetic level, i.e: when cotton threads are embedded into the biomass, the fungal network is able to grow around the cotton, reinforcing the material.

The foam is then harvested after 2 weeks, and sent for further processing, turning the mycelium network into sheets of material that resembles cork, but much more pliable and thin. It is then tanned and dyed to replicate the look and feel of real leather without involving animals, resulting in Mylo, ready to be shipped to fashion houses. The leftovers can be composted and reused in the existing productions, closing the loop on waste.

Mylo’s carbon footprint is extremely miniscule, considering it could be harvested in two weeks, compared to rearing animals for leather, which takes up a lot of resources and many years to raise. It is also free from the commonly used substances in animal and synthetic leather production, chromium, and DMF (dimethylformamide), both of which are highly hazardous to our health.

Mylo is now available in a wide range of textures and thickness, from pebbled, to flexible and ultra-soft. Stella McCartney and Adidas are two of the most notable names to embrace the innovative mushroom leather in their collections.

Desserto

Two entrepreneurs in Mexico, Adrian Lopez Velarde and Marte Cazarez came together to create Desserto, a vegan, organic leather derived from cactus. The revolutionary vegan leather feels very similar to real leather; it’s soft, durable, flexible, and durable, making it an ideal replacement for animal and synthetic leather. The idea of using nopal or prickly-pear cactus is because the crop grows in abundance all across Mexico without requiring any water, thus making it a low-impact crop.

The durability and elasticity of the material makes it suitable for a variety of uses, from fashion, furniture, to automobiles. “After two years of research and development, we managed to produce a suitable material that complies with the features and technical/mechanical specifications required by those industries that use animal and synthetic leather,” said Lopez. It’s also free from toxic chemicals, phthalates, PVC, partially biodegradable, and is highly sustainable with less carbon offsets.

The cruelty-free product debuted at the International Leather Fair Lineapelle in Milan in 2019, and was much talked about at the RawAssembly, Australia’s first sustainable fabric sourcing event for the fashion industry. Earlier this year, Desserto collaborated with H&M for their Science Story collection, which is part of their Innovation Stories initiative.

Fleather by Phool

Phool didn’t exactly start out making sustainable textiles, but rather, it was a chance discovery. Before we dive into the rest of the topic, we should mention that Phool was already thriving as a circular company making incense sticks, incense cones, composts and Florafoam (a biodegradable Styrofoam alternative) out of flower waste.

The primary material that makes up Phool’s impressive repertoire of products, is the immense amount of flower waste discarded from temples and mosques into India’s most sacred river, the Ganges River. Ankit Agarwal, a former automation engineer, founded Phool as an effort to stop the Ganges from becoming a dumping ground for over 8 metric tons of toxic floral waste daily. According to the company's website, when the founders noticed the dyes, chemicals, and pesticides seeping from the flowers and into the river after people set them to float away on the water, they decided to do something about it, by upcycling flower waste

After a couple years into their business of working on their other flower-based products, Ankit and research scientist Saumya Srivastava noticed a thick, dense, and fibrous material that was growing on a pile of flower fibres in their factory. Upon closer inspection, the texture of the material resembled that of leather in terms of tensile strength and elasticity, and so their research into Fleather began.

To make Fleather, flower waste is collected and sorted according to species, weeding out garbage in the process (eg: plastic, thread, packaging, etc). The flowers are then broken down into petals, which will be made into an extract that Phool calls “a flower-based nutritive substrate”. From which a host of organisms are cultured and grown over the extract for 3 weeks, resulting in Fleather that feels exactly like the real deal.

Even though Fleather is yet to be sold on the market, the innovative product has already won a UN Sustainability Award and a PETA India award for Best Innovation in Fashion. Phool is already in talks with three global luxury fashion brands who are interested in using Fleather, which illustrates that there is demand for cruelty-free fabrics.

Orange Fiber

Orange Fiber is a silk-like fabric that’s the brainchild of Adriana Santanocito and Enrica Arena; and yes, as the name suggests, the fabric is conceived out of oranges, its byproduct to be exact.

In 2014, Adrianna, a Chemical & Pharmaceutical Technologies graduate, took a fashion design thesis idea to Enrica, with the idea of creating a sustainable fabric. Together the students innovated a process to generate the fabric, with the support of the Polytechnic University of Milan.

Over 700,000 tonnes of citrus fruit waste is produced annually in Italy alone, and no one has developed a viable alternative for its disposal, that is, until Orange Fiber. Adrianna and Enrica both recognized the potential for the use of these citrus byproducts, otherwise called “pastazzo”. The pastazzo will be processed at their pilot plant in Sicily, to extract the citrus cellulose which is then spun into yarn. The resulting silky cellulose yarn can be customized according to the designer’s needs. It could be blended with other materials for different properties, or tweaked to look shiny or opaque, though the Orange Fiber in its purest form has soft, lightweight, draping properties.

In 2017, Salvatore Ferragamobecame the first major fashion label to use Orange Fiber fabrics in its capsule collection. Later in 2019, H&M teamed up with Orange Fiber for their Conscious Exclusive collection, where the entire collection is made with recycled and sustainable materials. This shows the growing demand and interest in sustainable fabric alternatives.

The rising interest in conscious, vegan textiles have certainly accelerated the innovation of biofabrics, growing beyond indie fashion to widespread adoption by luxury brands. Though there was a time in the past when the majority of clothes were made from natural fibres, before the advent of fast fashion. By harnessing the potential of perishable waste, billions of tonnes of food could be saved from a trip to the landfills, and meet global demands of clean, sustainable fashion.